变色龙科技(惠州)有限公司

业务:13922474323(微信同号)公司电话:0752-6187789

公司传真:0752-6187789

公司地址:惠州市博罗县园洲镇禾山新世纪工业大道昌盛一楼

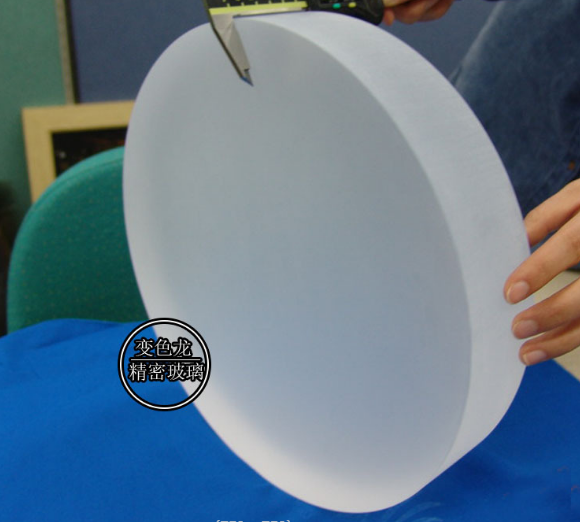

Quartz glass, also known as fused silica, is a high-purity, high-temperature resistant, and optically transparent material. It has a wide range of applications in various fields such as semiconductors, optics, aerospace, and medical equipment. Quartz glass is a challenging material to work with due to its high hardness and brittleness. However, with the development of advanced manufacturing techniques, it has become possible to shape and process quartz glass to meet the demanding requirements of various applications.

One of the most important techniques used in the processing of quartz glass is the etching process. Quartz glass etching involves the removal of material from the surface of the glass using chemicals. The process is widely used in the semiconductor industry to fabricate microstructures and patterns on the surface of quartz wafers. The process involves depositing a layer of photoresist on the surface of the glass, exposing it to ultraviolet light to transfer the pattern, and then immersing the wafer in an etching solution to remove the exposed areas.

Quartz glass etching has several advantages over other machining techniques. First, it can produce high-precision patterns and structures with sub-micron accuracy. Second, it does not cause any damage to the glass substrate, unlike mechanical machining techniques. Third, it is a relatively simple process that can be used to produce large quantities of identical patterns. Finally, the process can be customized to produce complex and three-dimensional patterns.

Quartz glass etching finds applications in various industries. In the semiconductor industry, it is used to fabricate microstructures, such as microelectromechanical systems (MEMS), and to pattern the surface of quartz wafers for integrated circuits. In the optics industry, it is used to produce complex and precise shapes for lenses, prisms, and optical fibers. In the medical industry, it is used to produce microfluidic devices, biosensors, and lab-on-a-chip devices.

To achieve the best results in quartz glass etching, it is important to use high-quality materials and follow the proper procedures. The etching solution must be of high purity and concentration, and the process parameters, such as temperature and etching time, must be carefully controlled. Furthermore, the equipment used for the etching process must be of high quality and properly maintained.

In conclusion, quartz glass etching is a powerful and versatile technique for shaping and processing quartz glass. It has found wide applications in various industries, including semiconductors, optics, aerospace, and medical equipment. With the continuous development of new materials and processes, it is expected that quartz glass etching will continue to play an important role in the manufacturing industry.